Pneumatic V-Type Adjustment Flange Ball Valve

Pneumatic V-Type Adjustment Flange Ball Valve

Nominal Pressure: 1.6MPa-6.4Mpa

Temperature: -28 ℃ ~ 500 ℃

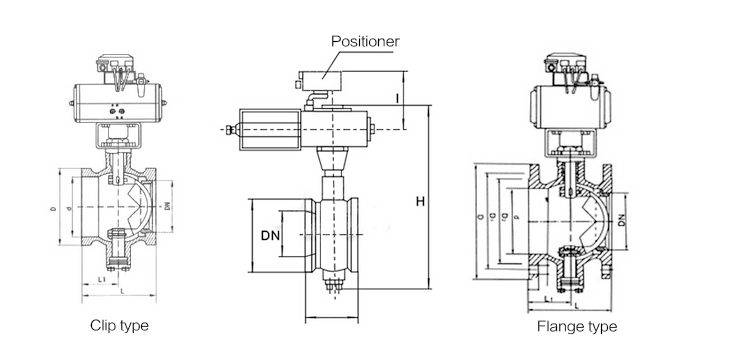

Connection: Clip-on, Flange

Body Material: WCB, ZG1Cr18Ni9Ti, ZG0Cr18Ni12Mo2Ti

Suitable Medium: Water, Steam, Oil, Nitric Acid, Acetic Acid

First, AT Pneumatic V-Type Adjustment Flange Ball Valve Introduction

AT pneumatic V-type adjustment flange ball valve pneumatic actuator with a new AT / GT series of pneumatic actuators, the structure of the national utility model patents, double and single acting (spring reset ), The use of rack and pinion structure transmission, more secure and reliable performance; large diameter valve with AW series of pneumatic actuators, fork fork structure structure, reasonable structure, the output torque.

AT pneumatic V-type flange ball valve according to the sealing performance is divided into soft seal and hard seal; according to the adjustment method is divided into adjustable and cut off type, cut off by the role of single-acting and double-acting, adjustable type for the double acting. The unique advantage of single acting is that once the power source fails, the ball valve will automatically be in the closed or open position as required by the control system.

Second, AT Pneumatic V-Type Adjustment Flange Ball Valve Works

AT aerodynamic V-type ball valve with a special shape of the fixed V-shaped incision ball and adjustable metal seat structure, when the valve is closed, V-shaped incision and the valve seat to form wedge shear Function, can prevent the ball and the seat between the dirt generated by the phenomenon of stuck, with self-cleaning function, especially for fiber-containing pulp, sewage and sticky particles of the media, coupled with the valve positioner can be continuously adjusted, and With a small flow resistance, wide adjustment range, is a wide range of high-quality control valve.

Third, AT pneumatic V-type Adjustment Flange Ball Valve Main Technical Parameters

1, the Valve Body

| Body Form | Through Casting Ball Valve |

| Nominal Diameter | DN25 ~ 400mm |

| Nominal Pressure | PN1.6, 2.5, 4.0, 6.4 MPa |

| Flange Standard | GB, JB, HG, ANSI, JIS and so on |

| Connection Form | Wafer Type, Flange Type |

| Bonnet Form | Integral (For Temperature -45 ~ + 400 ℃) |

| Gland Type | Bolt Compression |

| Sealed Packing | V-type PTFE Packing, Impregnated with polytetrafluoroethylene asbestos packing, asbestos textile filler, graphite filler |

2, Trim

| Spool Form | Spherical Spool With V-cut |

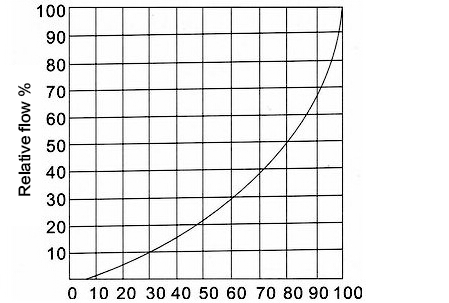

| Flow Characteristics | Approximate Percentage (see flow chart ) |

3, The Implementing Agency

| Actuator Type | AT / GT Series Pneumatic Actuators |

| The Main Technical Parameters | Supply Pressure: 400 ~ 700Kpa Air Supply Interface: G1 / 8 ", G1 / 4", G1 / 2 " |

| Ambient Temperature: -25 ~ +70 ℃, Ambient Humidity: ≤ 95 | |

| Accessories: locator, solenoid valve, air filter pressure relief valve, security valve, stroke switch, valve position transmitter, hand wheel institutions, etc. |

4, The Flow Characteristics (V adjust the ball valve of the inherent flow characteristics of the curve)

Fourth, AT Pneumatic V-Type Adjustment Flange Ball Valve Main Parts Material Table

| Material \ Material Code | C | P | R | |||

| The Main Parts | Body | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ||

| Ball Plate | 2Cr13 | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | |||

| Stem | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | |||

| Sealing Ring | Carbide | |||||

| Filler | Teflon, Soft Graphite | |||||

| Applicable Conditions | Applicable Media | Water, Steam, Oil | Nitric acid | Acetic Acid | ||

| Proper Temperature | -28 ° C to 500 ° C | |||||

5, AT Pneumatic V-Type Flange Ball Valve Product Performance Indicators

| Nominal Diameter (mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||||

| Rated Flow Coefficient Cv | 32 | 47 | 78 | 110 | 170 | 280 | 410 | 750 | 1120 | 1850 | 2950 | 3800 | |||||

| Nominal Pressure PN (MPa) | 1.6, 2.5, 4.0, 6.4 | ||||||||||||||||

| Flow Characteristics | Approximate percentage (see typical curve), straight line characteristics, quick opening | ||||||||||||||||

| Valve Plate Angle (Degrees) | 0 ° ~ 90 ° (adjustable) | ||||||||||||||||

| Allow The Leak Level | Soft Seal: Zero Leak Hard Seal: ≤10--5 Rated flow coefficient | ||||||||||||||||

| Form Of Action | Double Acting / Single acting (spring return type) | ||||||||||||||||

| Control Type | Cut off / Adjust type | ||||||||||||||||

| Actuator | Model | AT series, GT series, AW series, ZSQ series and so on | |||||||||||||||

| Air Pressure | Purify Compressed air (nitrogen) 0.3-0.7MPa | ||||||||||||||||

| Adjustable | Input Signal | Current Signal: 0 ~ 10mA, 4 ~ 10mA gas source signal 20 ~ 100kPa | |||||||||||||||

| Basic Error | With Locator ≤ ± 1.5% | ||||||||||||||||

| Backlash | With Locator ≤ 1.5% | ||||||||||||||||

| Dead Zone | With Locator ≤ 0.6% | ||||||||||||||||

| Adjustable Ratio | 250: 1 | 300: 1 | |||||||||||||||

| Cut off Type | Return Voltage | AC220V, AC110V, DC24V, | |||||||||||||||

| Cut off Time | 0.5 S | 1.0 S | 2.5 ~ 4.0 S | 7.0 S | |||||||||||||

| PN (MPa) | DN (mm) | Size (mm) | ||||||||

| L | Folder Connection | Flange Connection | H | |||||||

| D | D | D1 | D2 | D6 | b | zd | ||||

| 1.6 | 25 | 102 | 64 | 115 | 85 | 5 | - | 14/16 | 4-14 | 233 |

| 40 | 114 | 82 | 145/150 | 110 | 85/84 | - | 16/18 | 4-18 | 280 | |

| 50 | 124 | 100 | 160/165 | 125 | 100/99 | - | 16/20 | 4-18 | 362 | |

| 65 | 145 | 118 | 180/185 | 145 | 120/188 | - | 18/20 | 4-18 | 377 | |

| 80 | 165 | 130 | 195/200 | 160 | 135/132 | - | 20 | 8-18 | 410 | |

| 100 | 194 | 155 | 215/220 | 180 | 155/150 | - | 20/22 | 8-18 | 423 | |

| 125 | 210 | 185 | 245/250 | 210 | 185/184 | - | twenty two | 8-18 | 436 | |

| 150 | 229 | 216 | 280/285 | 240 | 210/211 | - | twenty four | 8-23 / 8-22 | 653 | |

| 200 | 243 | 264 | 335/340 | 295 | 265/266 | - | 26/24 | 12-23 / 12-22 | 703 | |

| 250 | 297 | 328 | 405 | 355 | 320/319 | - | 30/26 | 12-25 / 12-26 | 787 | |

| 300 | 338 | 373 | 460 | 410 | 375/370 | - | 30/28 | 12-25 / 12-26 | 827 | |

| 2.5 | 25 | 102 | 64 | 115 | 85 | 65 | - | 16 | 4-14 | 233 |

| 40 | 114 | 82 | 145/150 | 110 | 85/84 | - | 18 | 4-18 | 280 | |

| 50 | 124 | 100 | 160/165 | 125 | 100/99 | - | 20 | 4-18 | 362 | |

| 65 | 145 | 118 | 160/185 | 145 | 120/118 | - | twenty two | 8-18 | 377 | |

| 80 | 165 | 130 | 195/200 | 160 | 135/132 | - | 22-24 | 8-18 | 410 | |

| 100 | 194 | 155 | 230/235 | 190 | 160/156 | - | twenty four | 8-23 / 8-22 | 423 | |

| 125 | 210 | 185 | 270 | 220 | 188/184 | - | 28/26 | 8-25 / 8-26 | 436 | |

| 150 | 229 | 216 | 300 | 250 | 218/211 | - | 30/28 | 8-25 / 12-26 | 653 | |

| 200 | 243 | 264 | 360 | 310 | 278/274 | - | 34/30 | 12-25 / 12-26 | 703 | |

| 250 | 297 | 328 | 425 | 370 | 332/330 | - | 36/32 | 12-30 | 787 | |

| 300 | 338 | 373 | 485 | 430 | 390/389 | - | 40/34 | 16-30 | 827 | |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552