Manually mounted upward discharge valve

Manually mounted upward discharge valve

Nominal diameter: DN50 ~ 200mm

Nominal pressure: PN1.0 ~ 6.4MPa

Applicable temperature: -29 ~ 650 ℃

Main material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8, CF8M, CF3, CF3M

drive : manual, pinion drive, pneumatic, electric, hydraulic, gas-hydraulic, electro-hydraulic linkage

suitable medium: water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media

[Basic Information]

The discharge valve is mainly used for the bottom of the reactor, tank and other containers, and is welded to the bottom of the tank and other containers by means of the bottom flange of the valve, thus eliminating the residual phenomenon of the process medium usually at the container outlet. Discharge valve according to the actual situation needs, put the bottom structure designed for the flat type, the valve body for the V-type, and provide lifting and lowering the two working methods valve. Valve body cavity with anti-erosion, corrosion-resistant seals, in the open valve moment, you can protect the valve body is not washed, corrosion, and special treatment of the seal, the surface hardness of HRC56 ~ 62, with high wear , Corrosion-resistant function. Valve seal according to the needs of the cover are covered with cemented carbide, sealed by the use of line seal to ensure the reliability of the seal, and to prevent scarring. At the same time, take the design of the short stroke valve. In the chemical industry, petroleum, metallurgy, pharmaceutical, pesticide, dyes, food processing and other industries widely used. Various modes of operation, such as manual, pneumatic (spring return type, double acting type, with hand wheel and without hand wheel), electric, hydraulic, gear and so on.

[Standard parameter]

| design standards | GB / T 12235 |

| Connection standard | GB / T 9113, HG / T 20592, HG / T 20615 |

| pressure test | JB / T 9092 |

[Valve Features]

1, the valve body with resistance to erosion, corrosion-resistant seals.

2, the valve seal according to the need when the cover are welded with a carbide, with high wear resistance, corrosion resistance.

3, a variety of modes of operation, such as manual, pneumatic (spring reset, double acting, with hand wheel and without hand wheel), electric, hydraulic, gear and so on.

[Adaptation]

The discharge valve is mainly used for the bottom of the reactor, tank and other containers, discharge, sampling and no dead zone shutdown operation. By means of the bottom of the valve flange welded to the bottom of the tank and other containers, thus eliminating the process medium is usually the phenomenon of the container at the exit of the discharge valve according to the actual situation, the bottom structure designed for the flat, , And offers both lifting and lowering of the working flap.

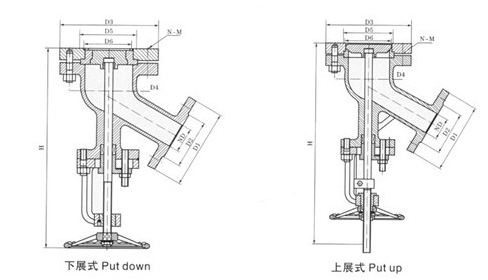

[Structure diagram]

[On the type of discharge valve connection size]

| DN | On the flange | On the flange | Under the flange | Seal seat | ||

| D1 | D2 | D3 | D4 | D5 | D6 | |

| 25 | 115 | 80 | 115 | 85 | - | - |

| 32 | 135 | 100 | 135 | 100 | - | - |

| 40 | 145 | 110 | 145 | 110 | 80 | 60 |

| 50 | 165 | 125 | 160 | 125 | 85 | 70 |

| 65 | 180 | 145 | 180 | 145 | 130 | 85 |

| 80 | 195 | 160 | 195 | 160 | 135 | 95 |

| 100 | 215 | 180 | 215 | 180 | 160 | 130 |

| 125 | 245 | 210 | 245 | 210 | 160 | 140 |

| 150 | 280 | 240 | 280 | 240 | 185 | 165 |

| 200 | 335 | 295 | 335 | 295 | / | / |

[Under the release of the discharge valve connection size]

| DN | On the flange | On the flange | Under the flange | Seal seat | ||

| D1 | D2 | D3 | D4 | D5 | D6 | |

| 25 | 115 | 85 | 135 | 100 | 70 | 40 |

| 32 | 135 | 100 | 145 | 110 | 75 | 55 |

| 40 | 145 | 110 | 160 | 125 | 100 | 65 |

| 50 | 165 | 125 | 180 | 145 | 85 | 70 |

| 65 | 180 | 145 | 195 | 160 | 135 | 90 |

| 80 | 195 | 160 | 215 | 180 | 155 | 130 |

| 100 | 215 | 180 | 245 | 210 | 195 | 135 |

| 125 | 245 | 210 | 280 | 245 | 180 | 145 |

| 150 | 280 | 240 | 335 | 295 | 210 | 185 |

| 200 | 335 | 295 | 405 | 355 | / | / |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552