Electric Flanged Soft Seal Butterfly Valve

Electric Flanged Soft Seal Butterfly Valve

Nominal Diameter: DN50 ~ 1000 (mm)

Nominal: PN0.6 ~ 4.0 (MPa)

Suitable Medium: Water, Steam, Oil, Acids and other corrosive

Body Material: Steel, 304

Flange Standard: GB, ANSI, DIN, JIS

Electric Actuator: Switch Type, Adjustable Type, Explosion-proof type

D941X series of Electric Flange Soft Butterfly Valve products from the rubber seal butterfly valve and carbon steel or stainless steel valve plate, stem composition. Applicable to the temperature ≤ 120 ℃ such as light textile, paper, food, medicine, chemical, oil, electricity, and other water supply and drainage, gas pipeline for regulating the flow and the role of interception medium. Its main features are:

1, The design of new, reasonable, unique structure, light weight, opening and closing quickly.

2, Operating torque is small, easy to operate, effort and dexterity.

3, Can be installed anywhere, easy maintenance.

4, The seal can be replaced, sealing performance reliable to achieve two-way seal zero leakage.

5, Sealing materials resistant to aging, corrosion resistance, long service life and so on.

Features

1, Powerful: intelligent, adjustable, switch-type.

2, Small size: the volume is only about 35% of similar products.

3, Easy to use: the use of single-phase power supply, wiring is simple; use of the original ball-shaped protruding structure, so that observation is more convenient; free refueling point inspection, waterproof rust, any angle installation.

4, The protection device has a double limit, overheating protection, overload protection. Full trip time of 15 seconds, 30 seconds, 45 seconds, 60 seconds.

Technical Parameters

| Nominal Diameter | DN (mm) | 50 ~ 1000 | ||||

| Nominal Pressure | PN (MPa) | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 |

| Test Pressure | Strength Test | 0.9 | 1.5 | 2.4 | 3.75 | 6.0 |

| Seal Test | 0.66 | 1.1 | 1.76 | 2.75 | 4.4 | |

| Gas Seal Test | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable Media | Water, Steam, Oil, Acid Corrosion and so on. | |||||

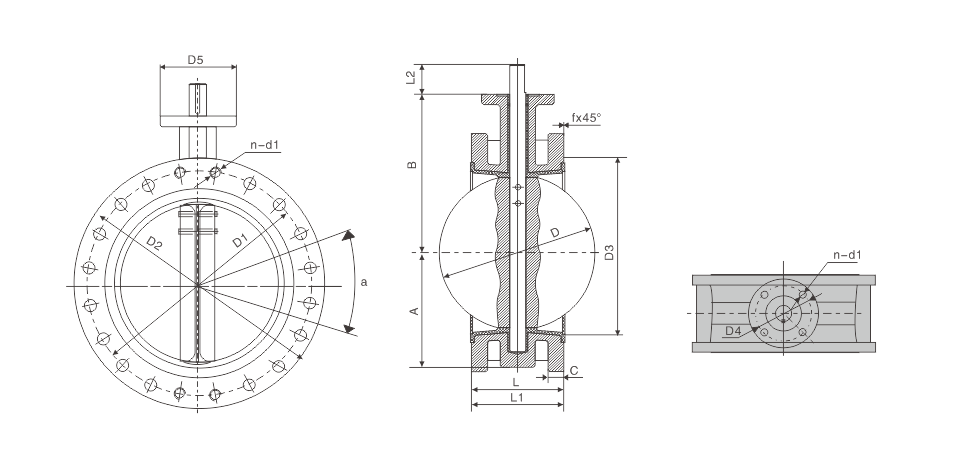

Main Dimensions and Weight (PN1.0 / 1.6MPa)

| DN (mm) | A | B | C | D | D1 | D2 | D3 | D4 | D5 | L | L1 | L2 | nd | a | f | n-d1 | Weight WT (kg) |

| 50 | 83 | 130 | 20 | 52.9 | 125 | 165 | 99 | 57.15 | 65 | 108 | 111 | 32 | 4-19 | 90 ° | 3 | 4-7 | 7.6 |

| 65 | 93 | 145 | 20 | 64.5 | 145 | 185 | 118 | 57.15 | 65 | 112 | 115 | 32 | 4-19 | 90 ° | 3 | 4-7 | 9.7 |

| 80 | 100 | 155 | 22 | 78.8 | 160 | 20 | 132 | 69.85 | 65 | 114 | 117 | 32 | 8-19 | 45 ° | 3 | 4-7 | 10.6 |

| 100 | 114 | 170 | 24 | 104 | 180 | 220 | 156 | 69.85 | 90 | 127 | 130 | 32 | 8-19 | 45 ° | 3 | 4-10 | 13.8 |

| 125 | 125 | 190 | 26 | 123.3 | 210 | 250 | 184 | 69.85 | 90 | 140 | 143 | 32 | 8-19 | 45 ° | 3 | 4-10 | 18.2 |

| 150 | 143 | 205 | 26 | 155.6 | 240 | 285 | 211 | 88.9 | 90 | 140 | 143 | 32 | 8-23 | 45 ° | 3 | 4-10 | 21.7 |

| 200 | 170 | 235 | 26 | 202.5 | 295 | 340 | 266 | 88.9 | 125 | 152 | 155 | 45 | 8-23 12-23 | 45 ° / 30 ° | 3 | 4-14 | 31.8 |

| 250 | 198 | 280 | 28 | 250.5 | 350/355 | 395/405 | 319 | 107.95 | 125 | 165 | 168 | 45 | 12-23 12-28 | 30 ° | 3 | 4-14 | 44.7 |

| 300 | 223 | 310 | 28 | 301.5 | 400/410 | 445/460 | 370 | 107.95 | 150 | 178 | 182 | 45 | 12-23 12-28 | 30 ° | 4 | 4-14 | 57.9 |

| 350 | 279 | 340 | 30 | 333.3 | 460/470 | 505/520 | 429 | 158.75 | 150 | 190 | 194 | 45 | 16-23 16-28 | 22.5 ° | 4 | 4-14 | 81.6 |

| 400 | 300 | 375 | 32 | 389.6 | 515/525 | 565/580 | 480 | 158.75 | 175 | 216 | 221 | 51.2 / 72 | 16-28 16-31 | 22.5 ° | 4 | 4-20.6 | 106 |

| 450 | 345 | 430 | 32 | 440.5 | 565/585 | 615/640 | 530 | 158.75 | 175 | 222 | 227 | 51.2 / 72 | 20-28 20-31 | 18 ° | 4 | 4-20.6 | 147 |

| 500 | 355 | 500 | 34 | 491.6 | 620/650 | 670/715 | 582 | 215.9 | 210 | 229 | 234 | 52.75 / 77.5 | 20-26 20-34 | 18 ° | 4 | 4-20.6 | 165 |

| 600 | 410 | 560 | 36 | 592.5 | 725/770 | 780/840 | 682 | 254 | 210 | 267 | 272 | 70.2 / 82 | 20-31 20-37 | 18 ° | 5 | 4-22 | 235 |

| 700 | 478 | 620 | 40 | 695 | 840 | 895/910 | 794 | 254 | 300 | 292 | 299 | 66/82 | 24-31 24-37 | 15 ° | 5 | 8-18 | 338 |

| 800 | 529 | 620 | 44 | 794.7 | 950 | 1015/1025 | 901 | 254 | 300 | 318 | 325 | 66/82 | 24-34 24-40 | 15 ° | 5 | 8-18 | 475 |

| 900 | 584 | 665 | 46 | 864.7 | 1050 | 1115/1125 | 1001 | 254 | 350 | 330 | 338 | 118 | 28-34 28-40 | 12.9 ° | 5 | 8-22 | 595 |

| 1000 | 657 | 735 | 50 | 965 | 1160/1170 | 1230/1255 | 1112 | 254 | 350 | 410 | 417 | 141 | 28-37 28-43 | 12.9 ° | 5 | 8-22 | 794 |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552