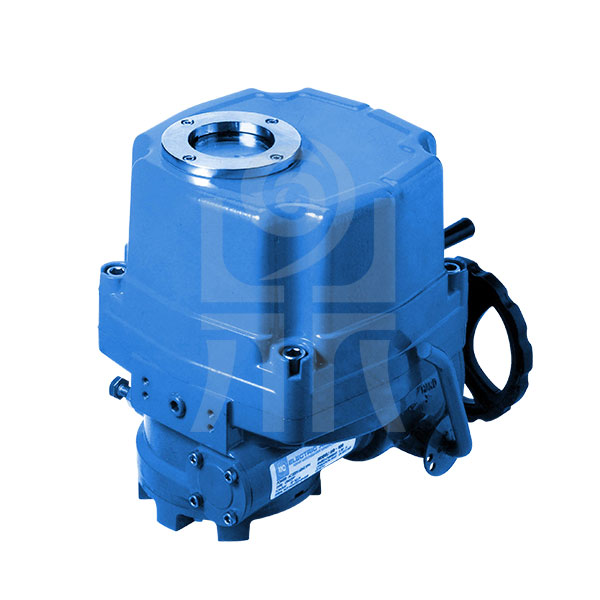

Electric Actuator

Electric Actuator

Motor Power: 110 / 220V AC 1PH, 380 / 440V AC 3PH, 50 / 60Hz, ± 10%

Control Power: 110 / 220V AC 1PH, 50/60 Hz, ± 10%

Motor: Squirrel Cage Asynchronous Motor

Limit Switch: 2 X on / off, SPDT, 250V AC 10A

Stall Protection /Operating Temperature: built-in thermal protection, open 150 ℃ ± 5 ℃ / off 97 ℃ ± 15 ℃

Ambient Temperature: -20 ℃ ~ +70 ℃

A Brief Introduction To HQ Electric Actuators

1, Due to the use of high-quality aluminum alloy, light weight. And the inner and outer surfaces are anodized, and the outer surface is coated with polyester powder, and the corrosion resistance is strong.2, The motor - using SPG squirrel-cage motor, the output torque is large, and built-in thermal protection switch, the temperature control, to prevent damage to the motor.

HQ Electric Actuator Features

1, Shell - due to the use of high-quality aluminum alloy, light weight. And the inner and outer surfaces are anodized, and the outer surface is coated with polyester powder, and the corrosion resistance is strong.

2, The motor - using SPG squirrel-cage motor, the output torque is large, and built-in thermal protection switch, the temperature control, to prevent damage to the motor.

3, The moving structure - no power, pull the clutch handle can be manually operated. When energized, the clutch is automatically reset.

4, The position indicator - the indicator is installed on the central axis, you can observe the valve position. And the indicator light (SLU) to choose from.

5, Dryer - used to control the temperature, to prevent the internal condensation of the actuator, to keep the internal electrical components of the dry.

6, Limit switch - by the cam mechanism to control, a simple adjustment mechanism can accurately and easily set the location.

7, Torque switch (except HQ-008 outside) - can provide overload protection, to prevent damage to the motor. (Set before the factory is set, please do not change the settings of the user).

8, Self-locking - a self-locking function to prevent reversal, rotating part of the stable and reliable.

9, The installation - the bottom of the installation size in line with ISO5211 international standards, drive sleeve can be removed according to the need for processing, strong adaptability. Can be installed vertically or horizontally.

10, The terminal - the circuit layout is compact and reasonable, the terminal diameter of 2.5mm, pressure, strong connection.

11, Worm gear - with concave wheel design, and the contact surface with the worm, transmission torque, smooth and wear, long service life.

12, PCU board - compact and reasonable, the PCU board built in the case.

HQ Electric Actuator Performance Parameters

| Model | Maximum Output Torque | Action Time | Maximum Shaft Diameter | Motor Class F | Rated current (A) 60 / 50Hz | Handwheel Turns | Weight | |||

| 60 / 50Hz | Simplex | Three Phases | ||||||||

| Kg-m | 90 ° | MM | W | 110V | 220V | 380V | 440V | N. | Kg | |

| HQ-008 | 8 | 13/16 | Ф20 | 15 | 1.10 / 0.95 | 0.55 / 0.54 | N / A | N / A | 10 | 7.4 |

| HQ-015 | 15 | 21/25 | Ф22 | 40 | 1.65 / 1.67 | 0.88 / 0.84 | 0.31 / 0.31 | 0.30 / 0.31 | 11 | 16.6 |

| HQ-020 | 20 | 21/25 | Ф22 | 40 | 1.67 / 1.67 | 0.89 / 0.85 | 0.31 / 0.31 | 0.30 / 0.31 | 11 | 16.6 |

| HQ-030 | 30 | 26/31 | Ф35 | 40 | 1.85 / 1.86 | 0.92 / 0.92 | 0.35 / 0.35 | 0.34 / 0.34 | 13.5 | 22 |

| HQ-050 | 50 | 26/31 | Ф35 | 90 | 3.60 / 3.62 | 1.55 / 1.58 | 0.59 / 0.59 | 0.58 / 0.58 | 13.5 | 23 |

| HQ-060 | 60 | 26/31 | Ф35 | 90 | 3.65 / 3.62 | 1.60 / 2.20 | 0.60 / 0.59 | 0.59 / 0.58 | 13.5 | 23 |

| HQ-080 | 80 | 31/37 | Ф45 | 180 | 4.10 / 4.10 | 2.15 / 2.20 | 0.85 / 0.85 | 0.79 / 0.79 | 16.5 | 29 |

| HQ-120 | 120 | 31/37 | Ф45 | 180 | 4.20 / 4.10 | 2.35 / 2.30 | 0.87 / 0.87 | 0.81 / 0.81 | 16.5 | 29 |

| HQ-200 | 200 | 93/112 | Ф65 | 180 | 4.10 / 4.10 | 2.15 / 2.30 | 0.85 / 0.85 | 0.79 / 0.79 | 49.5 | 75 |

| HQ-300 | 300 | 93/112 | Ф65 | 180 | 4.20 / 4.10 | 2.35 / 2.30 | 0.87 / 0.87 | 0.81 / 0.81 | 49.5 | 75 |

HQ Electric Actuator Standard Parts Technical Parameters

| Sshell | Waterproof Class IP67, NEMA4 and 6 |

| Motor Power Supply | 110 / 220V AC 1PH, 380 / 440V AC 3PH, 50/60 Hz, ± 10% |

| Control Power Supply | 110 / 220V AC 1PH, 50/60 Hz, ± 10% |

| Load rate (switch) | S2 30% |

| Motor | Squirrel Cage Induction Motor |

| Limit Switch | 2 X ON / OFF, SPDT, 250V AC 10A |

| Auxiliary Limit Switch | 2 X ON / OFF, SPDT, 250V AC 10A (except HQ-008) |

| Torque Switch | On / Off, SPDT, 250V AC 10A (except HQ-008) |

| Stroke | 90 ° ± 10 ° (0 ° ~ 110 °) |

| Stall Protection / Operating Temperature | Built-in Thermal Protection, Open 150 ℃ ± 5 ℃ / off 97 ℃ ± 15 ℃ |

| Indicator | Continuous Position Indication |

| Manual Operation | Mechanical Clutch Mechanism |

| Self-locking Device | Worm Gear, Worm Mechanism to Provide Self-locking |

| Mechanical Limit | 2 External Adjustment Bolts |

| Dryer | 7-10W (110 / 220V AC) Anti-condensation |

| Wiring Holes | 2 PF 3/4 " |

| Ambient Temperature | -20 ° C to + 70 ° C |

| lubricating | Aluminum Grease (EP type) |

| Material | Steel, Aluminum Alloy, Aluminum Bronze, Polycarbonate |

| Environment Humidity | Maximum 90% RH (non-condensing) |

| Seismic Performance | XYZ 10g, 0.2 to 34 Hz, 30 minutes |

| Outer Coating | Dry Powder, Epoxy Polyester |

HQ Electric Actuator Optional Technical Parameters

| EXA | Explosion-proof Housing (Eexd II CT6) | HQ Series |

| WTA | Waterproof Housing (IP68, 10M, 250HR) | HQ Series |

| PIU | Potentiometer (1K-10K) | Except HQ-008 |

| IMS | Reverse Electromagnetic Control and Transmission of Integrated Motor Starters | Except HQ-008 |

| PCU | Proportional Control Unit (Input, Output 4-20mADC) | Except HQ-008 |

| ATS | Additional Torque Switch (SPDT X2 250V AC 10A) | Except HQ-008 |

| LCU | Field Control Unit (Remote Control / On / Off / Off Selection Switch) | Except HQ-008 |

| CPT | Current Position Sensor (Output 4-20mADC) | Except HQ-008 |

| RBP | Rechargeable Battery (Power Emergency Control) | Except HQ-015,020,030,050 |

| EXT | 120 °, 180 °, 270 ° Angle | Except HQ-200,300 |

| DCM | DC Motor (24VDC) | Except HQ-015,020,030 |

| LPA | Horizontal Installation With Output Arm | Except HQ-008 |

| SLU | Signal Indicating Unit (White - Power Supply, Green - Open, Red - Off, Yellow - Torque Overload) | Except HQ-008 |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552